Projects

Pressure Reducing Hydrant Valves

Scope of Work

Clearwater Fire Solutions were approached by an existing client to help and source several 3" Pressure Reducing Hydrant Valves. These valves would swap out existing products currently installed offshore that were starting to show degradation. Following several discussion with the client and requests with manufacturers the products were confirmed in design and manufactured.

Results

The Pressure Reducing Hydrant Valves were delivered to our client successfully and are currently being installed across a number of offshore assets across the UK North Sea.

North Sea Operator

Scope of Work

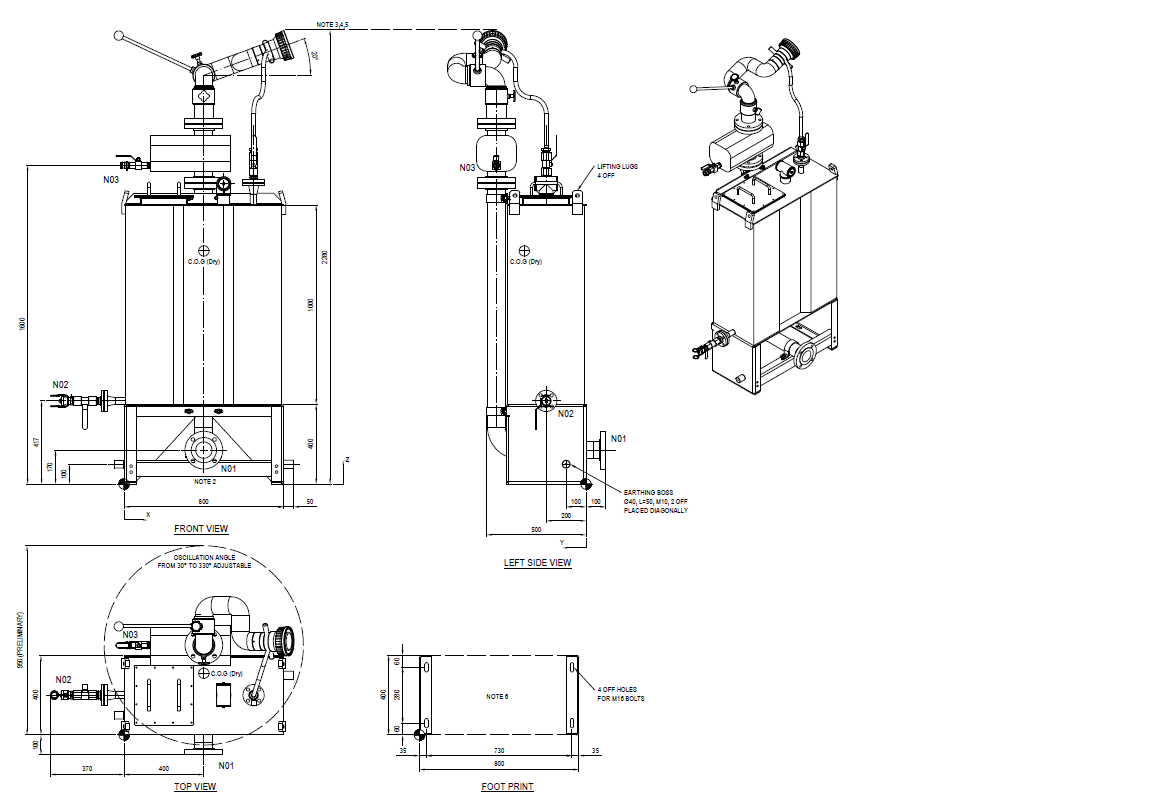

This large North Sea Operator requested Clearwater Fire Solution to design, build and install two Heli-Deck Self Oscillating Foam Monitors. Clearwater Fire collaborated with their partners FPE Sontum AS to complete this scope of work. FPE Sontum were able to FAT both monitors with thanks to their purpose build testing facility in Stavanger.

Due to COVID restrictions both client meetings and the final FAT were completed through online meetings and live demonstrations. Great communications between the teams ensured the project was delivered on time and to specification. Our Clearwater Fire team mobilised to arrive onboard prior to the skids being offloaded from the supply vessel. The team ensured the seamless installation and commissioning of the skids. Minor adjustments were required to ensure the foam properties were inducting at the correct percentage and this was done using our travel foam testing kit.

- 2-man installation and testing team

- Foam Testing Kit

- Specialised tool kit

Results

Two fully functional Self Oscillating Foam monitors were designed, built, and installed to the client specification. Despite initial setbacks due to the COVID pandemic the scope of work was successfully completed on time and to specification.

International Client

Scope of Work

The International client approached Clearwater Fire with a request to test their deluge systems on the newly installed platform using the Siron Dry Testing technology, a main factor in the request is the corrosion under insulation concerns on the clients other platforms which have been directly linked to Wet Performance Testing. Following several demonstrations onshore and discussions with safety teams an equipment spread was mobilised to the platform in Q3 of 2020.

- 3 man-rope access team

- Dry testing work scope

Results

The Dry Testing of the three jacket platforms was successfully completed within one three-week trip. This project was completed safely and in addition to the work scope the Clearwater Fire team assisted in conducting potential dropped objects surveys with several items being removed and authorities informed.